BEST PRACTICES GUIDE PURE RESIN CO2 HOP EXTRACT

Pure Resin CO2 Hop Extract (CO2 Extract) is a hop product developed from the extraction of the components of hops that are important to brewers in the production of beer – namely the alpha-acids and essential oils that contribute to beer’s bitterness, aroma, foam, and microbiological stability.

INTRODUCTION

Pure Resin CO2 Hop Extract (CO2 Extract) is a hop product developed from the extraction of the components of hops that are important to brewers in the production of beer – namely the alpha-acids and essential oils that contribute to beer’s bitterness, aroma, foam, and microbiological stability. These are the compounds of the most benefit to brewers that are utilized from whole hops and hop pellets in the brewkettle during the brewing process that follow through into the final beer. CO2 Extract eliminates a great deal of the inert materials that come with the vegetative portion of hops and hop pellets, and thereby reduces weight, handling, and residual hop material that needs to be removed from the wort during brewing.

CO2 Extract is designed for use in the brewkettle or whirlpool on the “hot side” of brewing. Because the extract provides hop alpha acids – the same as those found in whole hops and hop pellets – the isomerization of these alpha acids into isoalpha acids is still necessary by means of the boiling process in the brewkettle (and to a lesser extent in the whirlpool). Also, as with whole hops and hop pellets, the timing of the addition of CO2 Extract in the process will influence the utilization of the various hop essential oils important in the flavor development in beer.

It should be noted that in making a transition from whole hops or hop pellets to CO2 Extract will improve the utilization of the alpha acids from the hops, but will also potentially affect the final aroma of the beer due to improved essential oil dispersion immediately following dosing and thereby the volatility and retention of the aroma compounds during the wort boil. Transitioning from whole hops or pellets, the brewer must expect some flavor differences to occur if CO2 Extract is to be used as a flavor contributor. However, if the objective for the use of CO2 Extract is exclusively to contribute to beer bitterness with little or no effect on hop aroma, the brewer can take comfort in knowing that the transition from whole hops or pellets to CO2 Extract can be accomplished with less concern regarding effects on beer aroma.

One caveat in the above statement: Brewers who use a high volume of hops in their process for beer styles with very high bitterness, e.g. greater than 40 IBU, must be cognizant of the effect of the hop vegetative material on beer flavor. There are various water-soluble components from hop vegetative material that at high dosage rates can contribute additional flavors and mouthfeel effects to the beer. Therefore, when making a transition to CO2 Extract, it is essential that trials be conducted to ensure an acceptable beer flavor profile be achieved. If present, flavor effects can be mitigated by replacing only a portion of the original hops, and then perhaps increasing the proportion over time so the transition is smooth without an abrupt and evident change.

Contact your Barth-Haas Sales or Technical representative to get recommendations for your particular circumstance and the goals you want to achieve.

DESCRIPTION

The dominant solvent used worldwide for extraction of hops is carbon dioxide (CO2), primarily as a supercritical fluid and to a lesser extent in the liquid state. CO2 Hop Extract contains the alpha acids, beta acids, essential oils, and other soft resin components of hops. The extract may be marketed as the undiluted resin (often called Pure Resin Extract) with an alpha acids content from 30% to 65%, depending on the characteristics of the original hops.

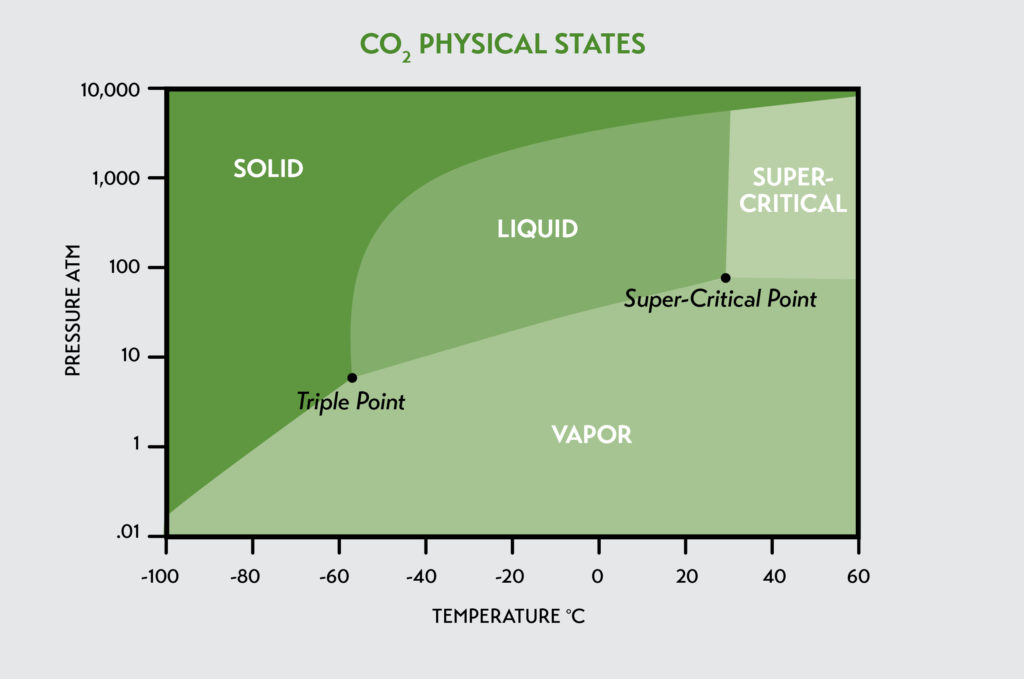

CO2 is normally a gas at ambient temperature and pressure, and if cooled sufficiently to -80˚C or lower, it will go directly into a solid phase, forming the familiar “dry ice.” However, increasing the pressure significantly along with an increase in temperature will result in liquid CO2 being formed. Further increasing the pressure and temperature will cause the CO2 to enter a super-critical fluid state – a phase that is not a gas, liquid, or solid, but is sometimes described as a plasma.

CO2 is normally a gas at ambient temperature and pressure, and if cooled sufficiently to -80˚C or lower, it will go directly into a solid phase, forming the familiar “dry ice.” However, increasing the pressure significantly along with an increase in temperature will result in liquid CO2 being formed. Further increasing the pressure and temperature will cause the CO2 to enter a super-critical fluid state – a phase that is not a gas, liquid, or solid, but is sometimes described as a plasma.

CO2 Extracts have many advantages over other hop kettle products:

- They are the most stable form of hop product. Pure resin extracts can be stored for several years at ambient temperature with negligible loss of brewing value.

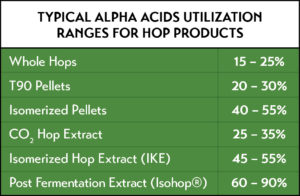

- Hop extract provides better utilization of alpha acids compared to other traditional non-isomerized kettle products.

- Hop extracts are extremely uniform. The alpha acids content in the container can be adjusted to customer specifications for optimum consistency.

- Shipping, storage weight, and volume are substantially reduced, as only the extract material is retained and packaged (typically 20 to 25% of the original hop material for high-alpha hops).

MATERIAL TRANSPORT AND STORAGE

As with any hop product, over time oxidation will reduce the bitterness potential of the alpha acids, and this effect will be accelerated if proper procedures are not followed for the transport and storage of the material. Of particular importance is the temperature range in which the products should be stored.

Products can be adversely affected when:

- Stored at temperatures above recommendations. This can result in an accelerated degradation of bitter compounds over time, resulting in the loss of product bittering potential.

- Storage temperatures are widely variable. Even if storage temperatures are kept within recommended limits, temperature consistency within a few degrees is best. This will ensure the optimum product stability.

Incidences of temporary high temperatures, although not optimal, will have only a minor effect on product performance, e.g. staging product in the brewhouse at high temperature prior to use.

RECOMMENDED TEMPERATURE RANGE FOR TRANSPORT AND STORAGE OF SPECIFIC PRODUCTS:

CO2 Extract is the most stable form of hops when its packaging remains intact. One of the real benefits of the product is its longevity when stored at ambient temperatures. As with other forms of classic hop products, i.e. whole hops and pellets, the colder the storage temperature the better this longevity, but pure resin extracts tolerate warmer temperatures quite well and there is little concern regarding the conditions of transport and storage. It is recommended, however, that prolonged storage above 30 degrees C be avoided if possible. With CO2 Extract, the temperature requirements are less stringent than those required for other hop products, and there is no minimum temperature limit other than the time and energy required to raise the temperature for proper handling and dosing when needed.

BEST-BY DATES

The “best-by date” is defined as the date until which the product should perform well without concern for product quality if stored according to recommendations.

The best-by date is not an expiration date, and the product may be perfectly suitable for usage past the best-by designation. It is merely the date at which the normal degradation of the components in the product can affect the bitterness potential and physical stability of the product. For many months beyond the best-by date, these deficiencies, if they occur, can be overcome with adjustments to the dosing rate for any diminished bitterness potential.

In addition, product that has been stored past the best-by date can show changes in its aroma profile due to oxidation reactions. Minor oxidation effects are of little or no consequence if the extract is used exclusively for beer bittering, i.e. added early in kettle boil.

If questions arise regarding the suitability of the product, whether in regard to temperature extremes or best-by designation, please contact your Barth-Haas Group sales and/or technical representative.

TYPES OF EXTRACT

Historically, pure resin extract was produced using various organic solvents, e.g. methylene chloride, hexane, to remove the resins from the hop plant material, but that has long passed. The most popular method now is using liquid or super-critical CO2 as a solvent. However, in Germany, there is an ethanol hop extraction plant in operation.

Both liquid and super-critical CO2 are very good solvents for the extraction of hop resins and the essential oils. So what’s best, liquid or super-critical CO2? Both are excellent solvents for the purposes of producing pure resin extracts. Super-critical CO2 is more efficient but requires much more robust pumps, piping, and extraction vessels due to the substantial increased processing pressures involved.

CO2 Hop Extract is mostly used in association with bittertype hops, providing an efficient method of extracting alpha acids for the bittering of beer. But because the hop essential oils are also effectively extracted, CO2 extraction of aroma and flavor hops is becoming popular.

For bittering, CO2 Extract is typically dosed into the brewkettle near the beginning of boil, much as is done with whole hops and hop pellets, but it disperses much more readily and provides a 10 to 15% (relative) increase in alpha acids utilization as compared to standard T90 hop pellets. In a typical lager brewing process, the upper limit of alpha acids utilization from CO2 Extract is about 35% (hop extract to finished beer); hop pellets max out at about 30%.

CO2 EXTRACT: NON-STANDARDIZED VERSUS STANDARDIZED EXTRACTS

CO2 Hop Extract itself will typically contain approximately four times the weight amount of hop acids and essential oils as found in the original hops and hop pellets from which it is derived, thereby providing a four-fold reduction in product weight, and an even more significant reduction in volume. A 15% alpha acids hops feedstock with 2% hop oil will produce extract containing about 55 to 60% alpha acids with about 8% hop oil. As with whole hops and hop pellets, the normal extract would be dosed according to its alpha acids and oil content to achieve the desired bitterness and aroma profile in the beer.

For convenience in dosing, CO2 Extract can be packaged in cans or small pails, delivering a specific alpha dosage per package unit, i.e. a set quantity of grams alpha acids per can. This can be done by mixing a diluent with the CO2 hop resin in the can – most often a sugar syrup–or by only partially filling a can to a volume that will contain the specified grams alpha acids. In either case, this is known as Standardized CO2 Extract. In most cases, Haas provides standardized extract as partially filled cans.

For convenience in dosing, CO2 Extract can be packaged in cans or small pails, delivering a specific alpha dosage per package unit, i.e. a set quantity of grams alpha acids per can. This can be done by mixing a diluent with the CO2 hop resin in the can – most often a sugar syrup–or by only partially filling a can to a volume that will contain the specified grams alpha acids. In either case, this is known as Standardized CO2 Extract. In most cases, Haas provides standardized extract as partially filled cans.

DOSING PROCEDURES AND OPTIMAL PERFORMANCE

There are many successful designs for CO2 Extract dosing, but there are many points to take into consideration for optimal product performance and utilization. A properly designed dosing system will ensure trouble-free performance of the product and provide a high level of product utilization and consistency in the final beer product. We highly recommend that the brewer take appropriate measures to provide a high-quality and precise dosing system that will ultimately repay a return on investment in optimum product utilization and performance.

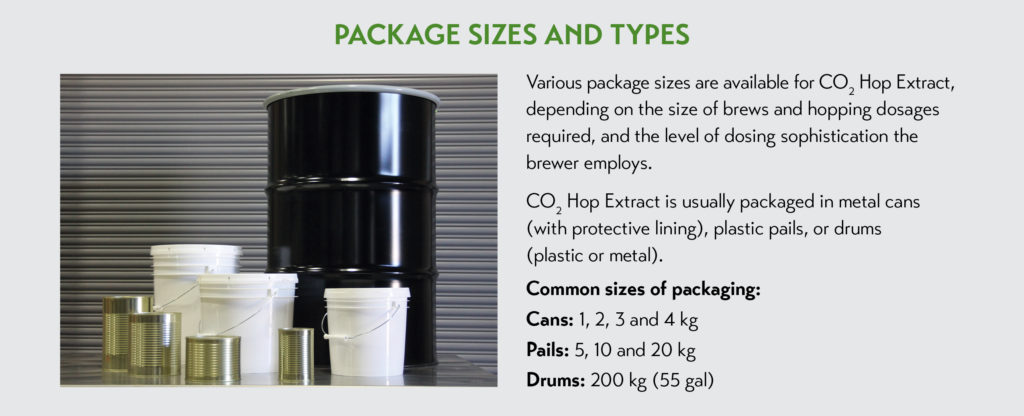

Depending on the size of the brew and the sophistication desired, there are a number of methods that can be utilized for dosing CO2 Hop Extract into the brew.

- Manually dosing full or partial cans or pails of extract directly into the kettle

- Suspending cans of extract individually or in a metal cage in the kettle

- External dosing units using cans or a measured quantity of extract

- Sophisticated systems for handling automated dosing of cans or drums of extract

When using extract in cans, a common procedure is to perforate the can top and bottom with several holes (3/4 in. or 15 to 20 mm) and suspend the can in the brew kettle above or just below the surface of the boiling wort. Alternatively, the top of the can may be removed and the open can placed under a tap in the grant during wort run-off. Another procedure is to liquefy the extract by placing the can in hot water, then pouring the extract slowly into the boiling wort.

If cans are suspended in the kettle, it is recommended that a container no larger than 4 kilos be used, since the time for the can to empty increases with can size, and the subsequent boiling time for dispersion and isomerization of alpha acids may be reduced, resulting in lower bittering yield.

Many brewers will utilize automated methods for hop extract dosing, which range from sophisticated external devices designed for circulating wort from the kettle through chambers holding cans to heated, enclosed chambers that will heat 200 kg drums of extract prior to directly pumping or transferring hop extract into dosing vessels. Confer with dosing equipment suppliers regarding their recommendations for your specific needs.

Any of these dosing procedures will give satisfactory results, but it is recommended that the brewer consult with a Haas sales or technical representative to determine the method that is most applicable for your brewery’s specific set-up.

DOSING CALCULATIONS

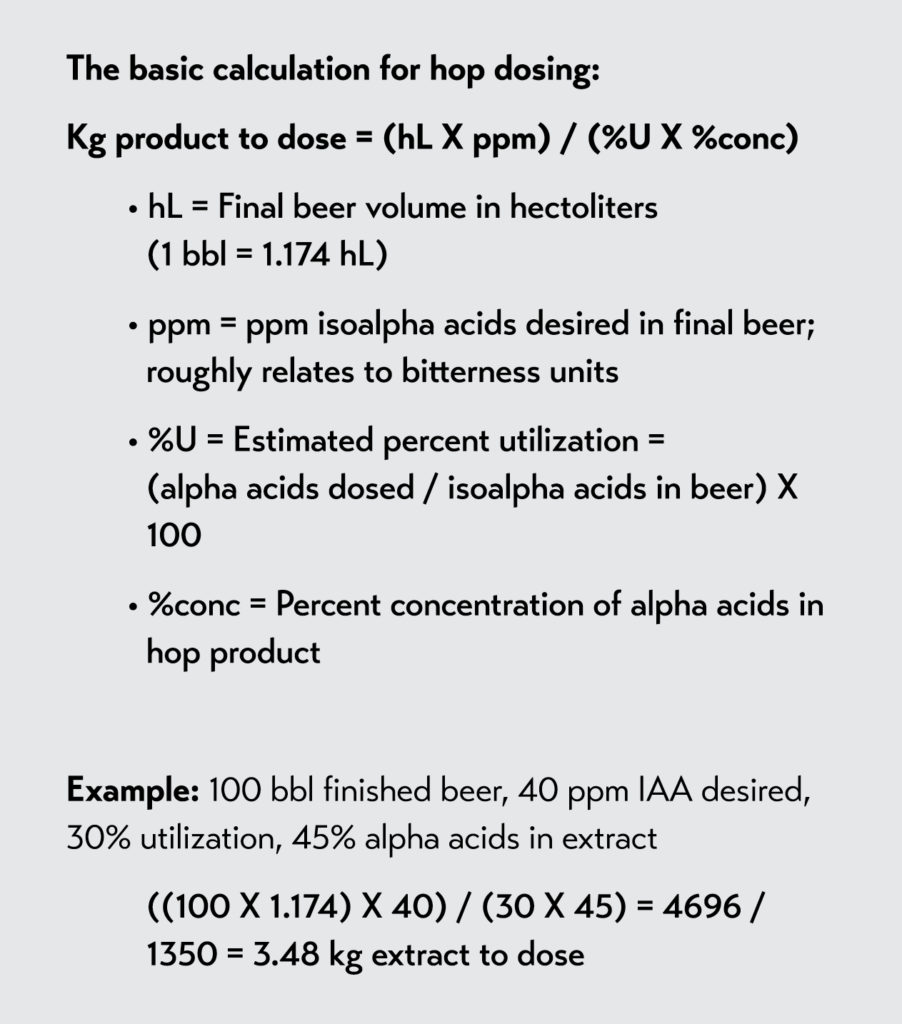

Conditions in different breweries vary so widely that no single formula is adequate for all breweries. From information provided by the brewer on hopping rate, type of hops used, and hop boiling schedule, a recommended initial dosage rate will be provided by Haas sales/technical personnel.

When replacing hop pellets with extract, it is usually recommended that the kettle dosage of alpha acids be reduced by 10 to 20% (typically, alpha utilization is increased by about 5% absolute, e.g. 25 to 30%).

Often, brewers choose to dose extract based on alpha content, particularly if standardized extract is used, e.g. extract can is filled with a specific quantity of alpha acids measured in grams (GMA). In this case, the %conc value should be entered as 100. Using the example above, modify with:

((100 X1.174) X 40) / (30 X 100) = 1.56 kg or 1,560 grams alpha to dose (or fill into a standardized can of extract).

The size of can used for a standardized addition depends on the total alpha for it to contain and the percentage of alpha in the extract. In the above example, the dosage requires 1.56 kg alpha residing in 3.48 kg of extract (1.56 / 45%). The brewer can choose the number and size of cans to have a standard fill per dose.

- One 4 kg size can with 3.48 kg extract; containing 1.56 kg alpha per can, or

- Two 2 kg size cans with 1.74 kg extract each; containing 780 grams alpha per can, or

- Four 1 kg size cans with 870 grams extract each; containing 390 grams alpha per can

CLEANING AND SANITATION

Because of the tendency for hop acid resins to stick to surfaces and build up, it is recommended that periodic cleaning be performed on any permanent dosing system. A cleaning procedure will usually be included in the operating instructions for commercial dosing units, and we recommend that those instructions be meticulously followed. For general periodic cleaning and maintenance, the system can be flushed with a caustic solution at a strength that is typically used for CIP cleaning, and can be performed during the scheduled CIP cleaning of the brew system.

The advantage of smaller, less sophisticated systems (external hop dosing units utilizing circulating wort, perforated cans suspended in the kettle, manual dosing from the package) is that upkeep is simplified with no routine cleaning or maintenance required. However,

there’s always a chance that hop extract will be spilled externally on equipment, flooring, clothing, and skin. It is recommended that personal protective equipment be worn when handling hop extract, including safety glasses, rubber or plastic disposable gloves, and protective clothing. Hop resin is not particularly hazardous but can be an irritant and difficult to clean using traditional soap/detergents and water.

Alcohol solutions such as 50% ethanol, 50% methanol, or 70% isopropanol work well for cleaning spills, but be aware that these are volatile solvents and appropriate caution should be taken when handling. For any cleaning that has exposure to the wort or beer steam, only ethanol should be used as opposed to the other alcohols mentioned. An alternative to ethanol is the use of a dilute potassium hydroxide solution (approx. 0.1 molar) for cleaning equipment. If using a caustic solution, it is important to follow

with a generous flush of distilled/deionized water.

FREQUENTLY ASKED QUESTIONS:

What is the best temperature for storing CO2 Extract?

CO2 Extract, when stored in its original unopened container, is the most stable of hop products available. When it is stored at room temperature, Barth-Haas gives the product a best-by designation of three years from time of production, but it could be suitable for use well beyond that time. If you have product approaching or beyond the best-by date, Haas can analyze a sample of the extract to determine if any appreciable degradation has occurred. The colder the temperature at which the extract is stored, the longer its longevity. The best-by date for CO2 Extract stored at 0 degrees F is eight years from the time of production.

How soon should the hop product be used once the original package is opened?

If stored at ambient or cooler temperature in its original container, the product should be used within a few weeks, or two months at most. For longer storage, the headspace in the package can be flushed with an inert gas such as nitrogen or CO2 and then resealed. Product that is heated and maintained at a warm temperature to facilitate dosing should be used within a few days of opening the container.

What if CO2 Extract is staged in a heated dosing vessel? How long can it be stored there?

Often, heated dosing vessels or drum heating units are used to warm the extract to a temperature of about 50 degrees C or more to liquefy and facilitate dosage. As with any hop product, time and temperature will affect oxidation of the hop acids and essence oils. If the product is not to be used within a couple of days, the temperature should be reduced and, if the vessel can be sealed, the headspace should be flushed with nitrogen or CO2. This will allow the product to be stored for about two weeks. The product should be heated and agitated again prior to the next dosing cycle. The dosing vessel or

heating unit is not a good long-term storage option for CO2 Extract; if the vessel cannot be flushed with an inert gas and sealed, care should be taken to schedule dosing to reduce residual product stored between dosing cycles for more than a couple of days.

Can I dose CO2 Extract into the whirlpool?

Yes, you can, but this only makes sense if you’re relying on extract for its aroma contribution. For bittering, the whirlpool is not the best option as you will get poor alpha acids isomerization. Also, adding extract to the whirlpool can result in less than optimum mixing and consistency, and possible resin deposition on the vessel walls. Our recommendation is to dose CO2 Extract into the brewkettle when possible, especially if you are utilizing the extract primarily for bittering. If either late kettle or whirlpool hop aroma is desired, trials should be conducted to evaluate the performance.